|

FLAMENCO is the new project I am engaged in as a researcher and a team leader. You can visit FLAMENCO (click)

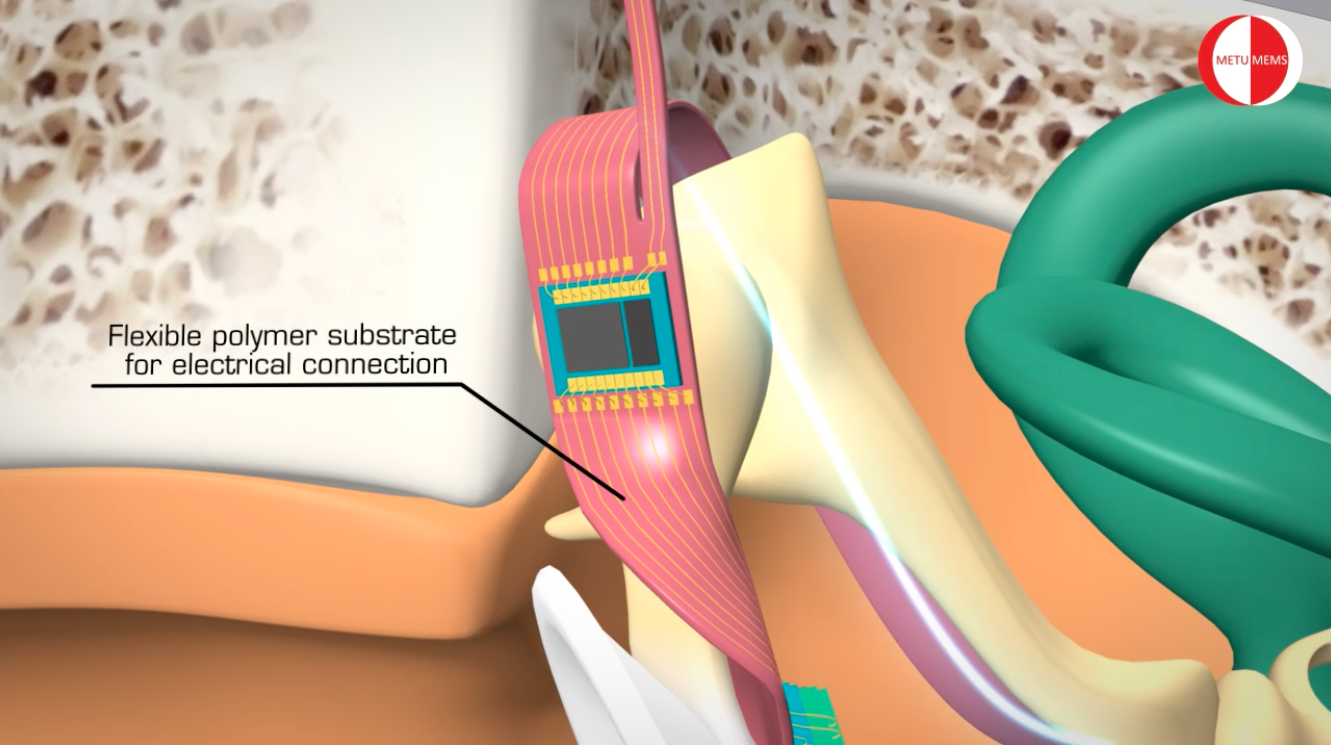

We are a multidisciplinary and multinational team of enthusiastic engineers (researcher and students) and doctors (Audiology) and we are dedicating our time to make the lives of hearing impaired easier. We posses knowledge of electronics, materials systems, mechanics, bio-mechanics and medicine. Provided that the project becomes successful in a short while it will help people in multiple ways. The research is conducted at the METU-MEMS center (50 Million US$) with clean room and research capacity that is at the international level. We use microfabrication tools to produce microscale devices and combine them with ICs to process the analog signals and turn them into the digital ones. Figure below illustrates the IC fixed on a flexible substrate that connects and regulates the signals of the sensor to the electrodes placed in the ear.

3 Comments

I have been working with transition metal oxides since 2005 (eg. WO3, TiO2). After starting my PhD at Ecole Polytechnique de Montreal in 2008, I started to work with Dr. Perepichkas group in McGill university who supplied upconverting nanoparticles for my project in hybrid organic-inorganic thin films for use in energy harvesting in the lost region of the solar spectrum. Here, the lost region implies the NIR region. Usually solar cells do not absorb in this area. I worked with Hexagonal NaYF4: Yb, Er nanoparticles for that study.

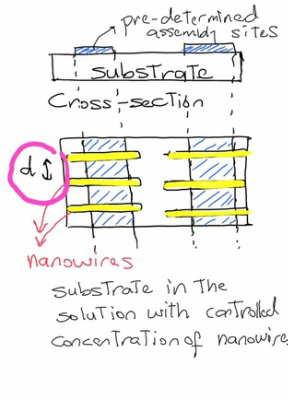

Keeping in mind that the energy transfer between species in close proximity and with a good energy level alignement can take place, I wanted to see how ucNP will behave when dispersed in a transition metal oxide matrix. Close to the end of my PhD, I designed an experiment using the nanoparticles provided by Dr. Perepichkas laboratory and the WO3 which I synthesized in the laboratory by sol-gel method. I mixed the ucNP with the prepared solution of WO3 and deposited a thick layer of the mixture onto a substrate with an ITO electrode (1000 um channel). The device was prepared as a 2 electrode device. Finally, I connected the electrodes to an Agilent B2100 series semiconductor parameter analyser unit and applied a potential between the two electrodes under dark conditions. The sample was kept under a black curtain during the experiments. When there was no excitation at the channel I did not observe any current flow in the channel. However, wehenever I excited the channel with a NIR (980 nm) laser I started to observe a current increase. I started to excite the ucNP-WO3 channel with NIR laser with intervals ( on-off) and I observed that the current was behaving accordingly. As a second step I increased the applied potential and observed an increase in the current flow as well. While increasing the current, I kept the laser power same. So, the only variable was the applied potential. To my knowledge, this made me the first person to show this kind of a current generation in a transition metal oxide- upconverting nanoparticle system. I would like to work more on this project later when I have my own laboratory. This work of mine lead to a collaboration with Ludvig Martinu group at Ecole Polytechnique de Montreal for NSERC grant application and collaborative work with Fiorenzo Vetrone group at INRS. The work was presented in several conferences. In the latest conferences my name was not included in the work. Probably because I am not a part of the group anymore, however the idea and the first demosntration of the principle belongs to me. If you are interested in knowing more, or if you are interested in the details of the work I will be glad to share my expertise in this area.  Today, I attended a seminar at École polytechnique de Montréal, by Theresa Mayer from Pennstate University.Topic is interesting due to the reported %90 yield of the manufacturing process and its applicability to electronic applications ( sensors, transistors, ...). Usually, research is stuck in the research laboratories due to the low yield, non-scalability ( lab-scale production or % error or high expense) or because they can not find applications in the market due the limitations such as service conditions, high price of the final product etc. I digged a bit the topic and here is a quick overview of the deterministic assembly process: (Not to be mixed with self assembly of materials (SAM)) (i.e. Ghadiri, M. R., Granja, J. R., Milligan, R. A., McRee, D. E. & Khazanovich, N. Self-assembling organic nanotubes based on a cyclic peptide architecture. Nature 366, 324–327 (1993)). Deterministic assembly of nano-structures is a promising production method because it is easy and accurate. Assembly methods are named after or according to the registry driving force employed for the process. Processes using electric or magnetic fields are classified as field-directed assembly and when the capillary forces is the main influencer that is called a directed capillary assembly. The process takes place by the application of an external electric field to the nano-structures ( preferentially in a non-polar liquid at low frequency and using AC-current) which drives the nanostructures to the predetermined assembly sites. For more information you can refer to the references listed below. Company of interest: IBM Research – Zurich, Säumerstrasse 4, 8803 Rüschlikon, Switzerland

Since some time I was thinking about the Scholar Google search and where it fails or where it is not so helpful. Finally, I sent a feedback to them requesting the following. Let's see if they will take of them and make life easier for many reserachers, students and others.

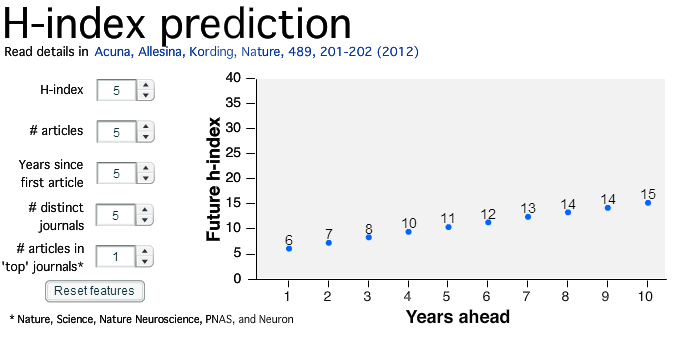

1- Rearranging the articles using the number of citations received 2- Having links to the author names presented in the articles on the search page to reach all their published articles: i.e. Scanometric DNA array detection with nanoparticle probes TA Taton, CA Mirkin, RL Letsinger - Science, 2000 - sciencemag.org when I click on the name of an author in the upper article it should give me the details of the author and all published papers. 3- Thumbnails of the article images (open/close option) This makes life sometimes easier, especially when you are looking for an image in a certain type of publication, you always need to see the source but it is not possible unless you click on it in the image search mode 4- Sorting the publications: article or review, so that we can easily locate reviews 5-Links to researchgate.com and academia.edu in the all versions sections, this will allow many researchers to have access to all articles since they are usually for a fee , these websites can publish them for free. Could you inform me when they are realized so that I can be aware and start using them. Thank you, Dilek ISIK I obtained my Ph.D. degree in Metallurgical Engineeringtoday (13.05. 2013). After 4 years and 10 months of hard work at Ecole Polytechnique de Montréal. The Jury members were: Prof. Yves-Alain Peter Prof. Clara Santato Prof. Sylain Turenne Prof. Ioannis Kymissis Prof. Fiorenzo VetroneMy sister and brother in law were there to support me and I think this support was very important due to the high level of stress during the process. Now, it is time to enjoy becoming a Ph.D.. I received a very special gift from my sister and brother in law today. I will keep it forever. Many young scientist are interested in knowing their progress in their careers. By use of statistical methods researchers made it possible to have an idea on the future success of the scientists. Research was based on 3085 neuroscientists. This study revealed that the future h-index or success in science can be predicted by a statistical method based on the h-index of the scientist and common CV features.

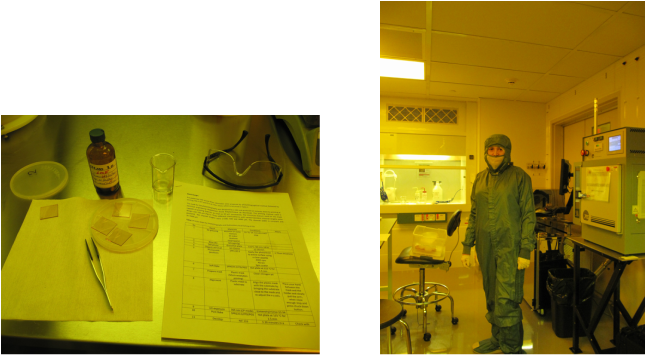

"The typical research CV contains information on the number of publications, those in high-profile journals, the h-index and collaborators. One can also infer interdisciplinary breadth, the length and quality of training, the amount of funding received and even the standing of the scientist's PhD adviser. Such factors are taken into account for hiring decisions, but how should they be weighted? Fortunately, obtaining data on the scientific activities of individual researchers has never been easier. Using all of these features, we can begin to probe the scientific enterprise statistically." Acuna, D. E., Allesina, S. & Kording, K. P. Future impact: Predicting scientific success. Nature 489, 201–202 (2012). The work was published in Nature and the data sources were Scopus and Academictree. To estimate your future success follow the link! It is also interesting to mention one of the articles cited in the above work, in the article a sentence highlights the importance of the h-index: "Based on typical h and m values found, I suggest (with large error bars) that for faculty at major research universities, h ≈ 12 might be a typical value for advancement to tenure (associate professor) and that h ≈ 18 might be a typical value for advancement to full professor. " Hirsch, J. E. An index to quantify an individual’s scientific research output. PNAS 102, 16569–16572 (2005). For more information on the statistical study follow the links below: http://tr.scribd.com/doc/109612801/Predicting-scientific-success http://klab.smpp.northwestern.edu/wiki/index.php5/Media I am really curious about the simple techniques that are reproducible and that can make life easier. Transparent conductive oxide coatings, especially ITO (indium tin oxide), are being used in many application areas such as solar cells, electrochromic windows and display devices. A grand majority requires micron sized patterned electrodes. Since I am working on a project that needs ITO electrodes in the micron range we applied for a Canadian Microelectronics Corporation Microsystems Micro-Nano Technology (CMC-MNT) financial assistance and got a good amount of support for the developement of a procedure by wet chemical etching. I prefered wet chemical etching instead of reactive ion etching because of the simplicity of the technique and the availability of the materials in every chemistry laboratory.

Lucikly, after making some litearture review on the subject I found some information on the etching process. Most results were not comparable although they claim to use the same etchants, but this is not very surprising to me because the deposition technique and the post-treatment processes of diferent ITO manufacturers are not the same. We will be publisihing the results as a part of a bigger project on electrolyte gating very soon. Tomorrow, Fiorenzo Omenetto will give a seminar in our department. I was looking forward to attending it since I learned about it. Almost two months ago I started working on the idea of having smart textiles usings silk as the skeleton. The first experiment was a complete trial and needs to be redone with care. Preliminary results are promising and the objective was to produce an organic semiconductor based field effect transistor which will be followed by oxide semiconductors by sol-gel based techniques. In a study by Müller et al. (2011)[1], an electrochemical transistor on silk fibers was demonstrated. Very low operating potentials were enough to operate the transistor which also proves that this kind of devices have a future in electronics sector. Thinking about the bio-compatible and bio-degradable properties of silk and devices that can work in electrolytic (aqueous) mediums one can consider manufacturing electronic devices that can be delivered to the body. The change in pH or the amount of chemical species can lead to a modulation in the current that enables the self powering of the devices in a closed loop. Of-course this depends on the magnitude of the current modulation and the materials (biocompatibility). [1] C. Müller, M. Hamedi, R. Karlsson, R. Jansson, R. Marcilla, M. Hedhammar, and O. Inganäs, “Woven Electrochemical Transistors on Silk Fibers,” Advanced Materials, vol. 23, no. 7, pp. 898–901, 2011. ---------------------------------------------------------------------------------------------------------------------- Here is a video I embedded from TED talks by Fiorenzo Omenetto. In a 10 minute talk he shows and presents some of the applications they worked on like packing(storage) materials for medicament, holograms, optical fibers and so on. You can find more on his research group website. Recent news on reverse engineered jellyfish is exciting. Scientists from USA (1) published an article on their study where a synthetically engineered life form mimics the muscle contraction of a jellyfish with 1Hz frequency. They used a silicon template and dissociated rat tissue to form a hierarchical design of a "muscle pump". And what if we were able to produce micro or nano sized muscle pumps to be used in electronics or other applications? This is an interesting point to explore in my opinion. The application areas would be diverse! Contraction and movement produces a force that can be used to open closed blood vessels?! Further reading and more videos on the jellyfish please follow the links: [1] J. C. Nawroth, H. Lee, A. W. Feinberg, C. M. Ripplinger, M. L. McCain, A. Grosberg, J. O. Dabiri, and K. K. Parker, “A tissue-engineered jellyfish with biomimetic propulsion,” Nature Biotechnology, Jul. 2012. [2] E. Yong, “Artificial jellyfish built from rat cells,” Nature, Jul. 2012. [3] G. Naik, “Lab-Made Jellyfish Hints at Fix for Damaged Hearts,” Wall Street Journal, 22-Jul-2012.  Zebra Fish (Wikipedia) Two weeks ago, a few of my friends and I got together for a picnic and a new friend was introduced to the group. Why I am telling this story is beacuse this new friend had one leg and lost the other one unexpectedly. Since that day I am more sensitive to the scientific works about body part regeneration and I started to read about the topic. I am sure most of you have already heard about the hobby-store owner who sliced his fingertip and it was later fully regenerated with the tissue, nerves, skin and the fingernail when he used a "magic powder", in 2005. You can watch the video that was shown on CBC news in 2008 (below). Since then the topic seemed to be more attractive or more mediatic. Whatever the reason is this is a very important step forward to grow body parts. Ofcourse, where the story ends science starts! Here are a few links to such scientific studies with different types of living organisms, i.e. Zebra Fish: [1] S. Pasqualetti, G. Banfi, and M. Mariotti, “The zebrafish scale as model to study the bone mineralization process,” Journal of Molecular Histology, pp. 1–7, 2012. [2] J. Itou, H. Kawakami, T. Burgoyne, and Y. Kawakami, “Life-long preservation of the regenerative capacity in the fin and heart in zebrafish,” Biology Open, 2012. [3] K. Agata and T. Inoue, “Survey of the differences between regenerative and non-regenerative animals,” Development, Growth & Differentiation, 2012. [4] “MicroRNAs Help Zebrafish Regenerate Fins,” ScienceDaily. [Online]. Available: http://www.sciencedaily.com/releases/2008/03/080314202107.htm [Accessed: 22-Jul-2012]. [5] Wikipedia contributors, “Zebrafish,” Wikipedia, the free encyclopedia. Wikimedia Foundation, Inc., 22-Jul-2012. Before I conclude, this history is interesting for me for other reasons too, because I believe that we can grow a fully functional tissue with all the nerves, flesh and skin to build non-human robots. Considering that the best nervous system is found in human-body this step can eliminate all the artificial sensor production steps and let us obtain a fully funtional texture. Artificial intelligence has already went far in terms of responsivity. Bringing together these two is hoped (by myself) to open a new path to manufacture super-intelligent robots. |

Archives

November 2017

Categories

All

|

RSS Feed

RSS Feed